LightWELD Handheld Laser Welder: Cost & Performance

In today's welding industry, efficiency, precision, and cost-effectiveness are crucial factors. Traditional welding methods like MIG and TIG have limitations in terms of speed, quality, and ease of operation. However, with the advent of the LightWELD Laser Welder, a game-changing technology, these limitations have been overcome.

The Power of LightWELD

The LightWELD Laser Welder transforms the welding process, offering superior advantages over conventional methods. It enables significantly faster welding, easier learning and operation, and consistently high-quality results across a wide range of materials and thicknesses. Unlike MIG or TIG welding, LightWELD minimizes distortion, undercut, and burn-through, resulting in a dramatically reduced heat-affected zone.

Unleashing the Potential of Handheld Laser Welding

With the LightWELD Laser Welder, traditional post-processing tasks such as grinding or polishing are minimized, leading to increased productivity, reduced scrap, and lower cost-per-part. This innovative technology streamlines the welding process, empowering businesses to achieve exceptional efficiency and deliver top-notch results.

Technical Specifications

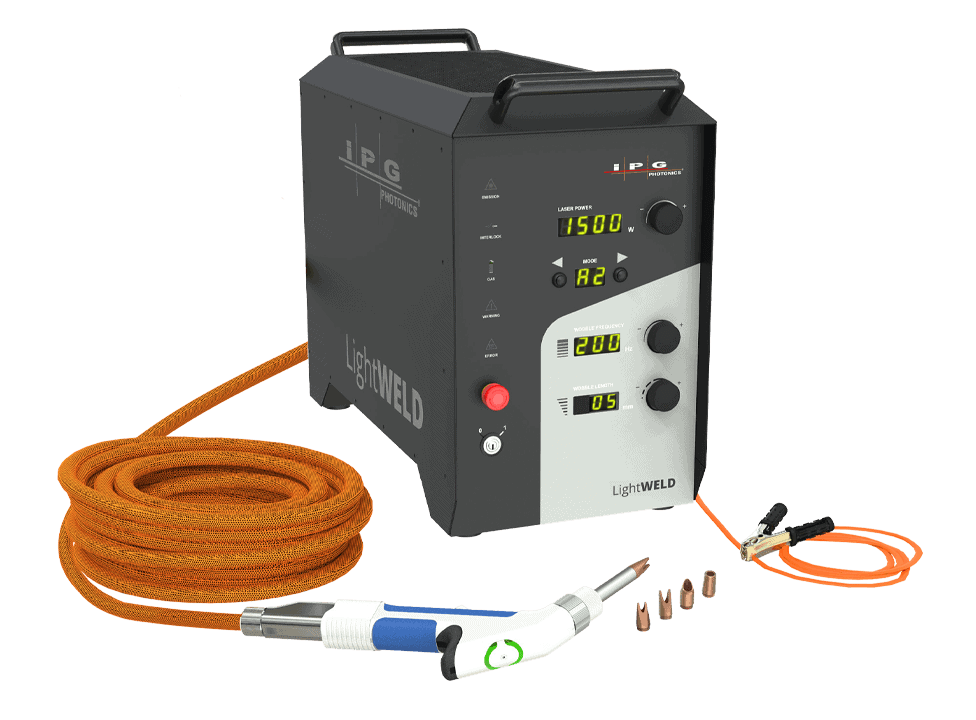

- Laser Power: The LightWELD Handheld Laser Welder offers adjustable laser power of up to 1500 W and high peak power of up to 2500 W. This flexibility allows for optimal weld settings across different materials and thicknesses.

- Single Sided Weld Thickness: Stainless Steel, Galvanized Steel, Mild Steel, and Aluminum: Up to 4 mm; Copper: Up to 1 mm.

- Included in the Package: Air-Cooled Base Unit, 5 m (16 ft) IPG Laser Welding Gun (Optional 10 m (32 ft) Cable), 5 m (16 ft) Workpiece Clamp (Optional 10 m (32 ft)), Getting Started Guide, and 4 Welding Nozzle Tips.

Applications of LightWELD Laser Welder

The LightWELD Laser Welder is suitable for a wide range of industries and applications, including:

- Metal fabrication shops

- Auto body applications

- Maintenance and repair

- Construction and piping

- Farming, furniture, and appliances

- Aerospace and transportation

Ext Material Range

The LightWELD Laser Welder is designed to accommodate various materials and thicknesses, providing exceptional versatility. Here is an overview of the supported materials and their respective welding thickness capabilities:

- Stainless Steel: Up to 4 mm (single side weld), Up to 10 mm (double side weld)

- Mild Steel: Up to 4 mm (single side weld), Up to 10 mm (double side weld)

- Aluminum: Up to 4 mm (single side weld), Up to 10 mm (double side weld)

- Copper: Up to 1 mm (single side weld), Up to 2 mm (double side weld)

Features and Advantages

The LightWELD Laser Welder is packed with innovative features that enhance the welding experience and deliver exceptional results:

Adjustable Laser Power: The intuitive controls allow easy adjustment of laser power, making it effortless to find the optimal settings for different materials and thicknesses. With 74 stored preset and user-defined process parameters, even novice welders can learn and start welding within hours.

Process Automation & Programmability: LightWELD offers predefined welding parameters for consistent, high-quality welds. The system reduces training and production costs by allowing novice welders to quickly access stored modes and user-defined process parameters. This ensures consistent weld quality while enabling rapid switching between different material-thickness combinations.

Compact Handheld Welding Gun: The LightWELD Laser Welder comes with a compact and ergonomic handheld welding gun. It is designed for comfort and ease of use, offering a well-balanced grip and a 2-step trigger. The lightweight design and built-in wobble functionality enable operators to produce high-quality welds consistently throughout the day.

Simple Installation and Operation: LightWELD is designed for hassle-free installation and operation. Welding fixtures are simpler or not required at all. Metals do not need to be pre-brushed or ground completely clean, saving valuable time. Even novices can reliably weld materials with different thicknesses and electrical conductivity without the need for extensive training.

Optional Wire Feeding Package: This add-on feature extends the laser welding applications to poorly fit-up parts. It can be used for low carbon steel, stainless steel, aluminum, and non-ferrous metals & alloys.

Frequently Asked Questions

Q: What materials can be welded using the LightWELD Laser Welder? A: The LightWELD Laser Welder is compatible with a wide range of materials, including stainless steel, mild steel, aluminum, and copper.

Q: Is the LightWELD Laser Welder suitable for novice welders? A: Yes, the LightWELD Laser Welder is designed to be user-friendly and can be easily learned by novice welders within hours.

Q: Can the LightWELD Laser Welder handle dissimilar thicknesses of metals? A: Absolutely. The LightWELD Laser Welder can reliably weld dissimilar metals with different thicknesses, thanks to its advanced technology and adjustable parameters.

Q: Does the LightWELD Laser Welder require extensive post-processing? A: No, the LightWELD Laser Welder minimizes the need for traditional post-processing tasks such as grinding or polishing, resulting in increased productivity and cost savings.

In Conclusion

The LightWELD Handheld Laser Welder is revolutionizing the welding industry, offering unprecedented speed, quality, and efficiency. With its advanced features, extensive material range, and user-friendly operation, businesses can achieve remarkable results while reducing costs and maximizing productivity. Embrace the power of LightWELD and forge forward into a new era of welding excellence.